188mm Brushless DC Ceiling Fan Motor for 72–100 Inch Industrial HVLS Fans

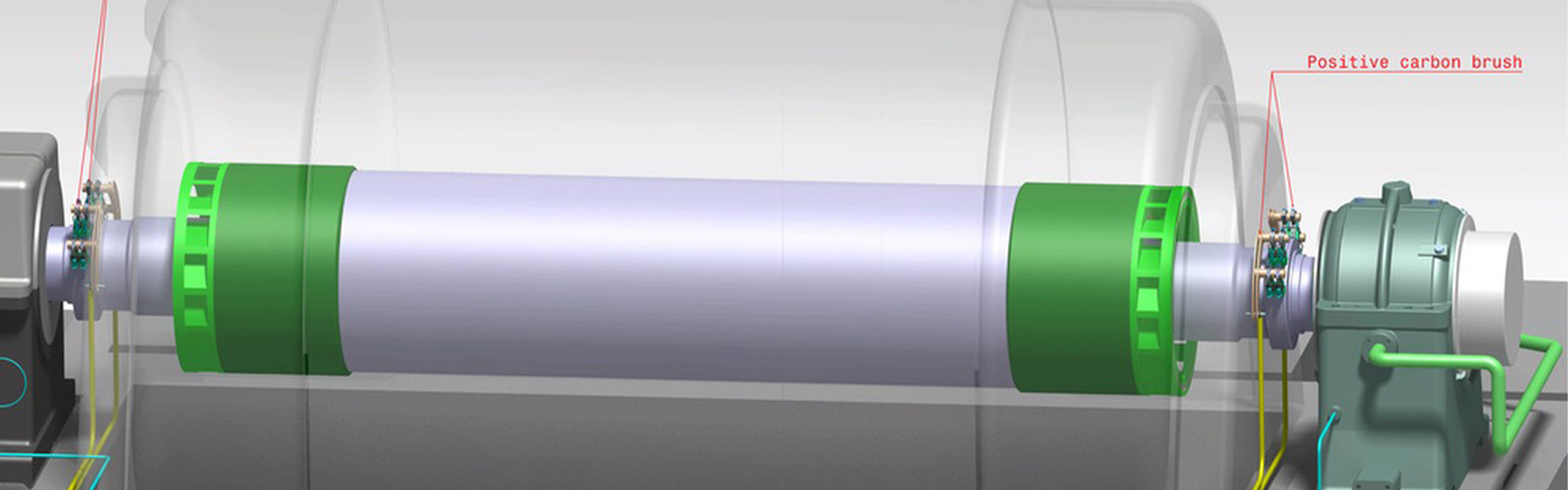

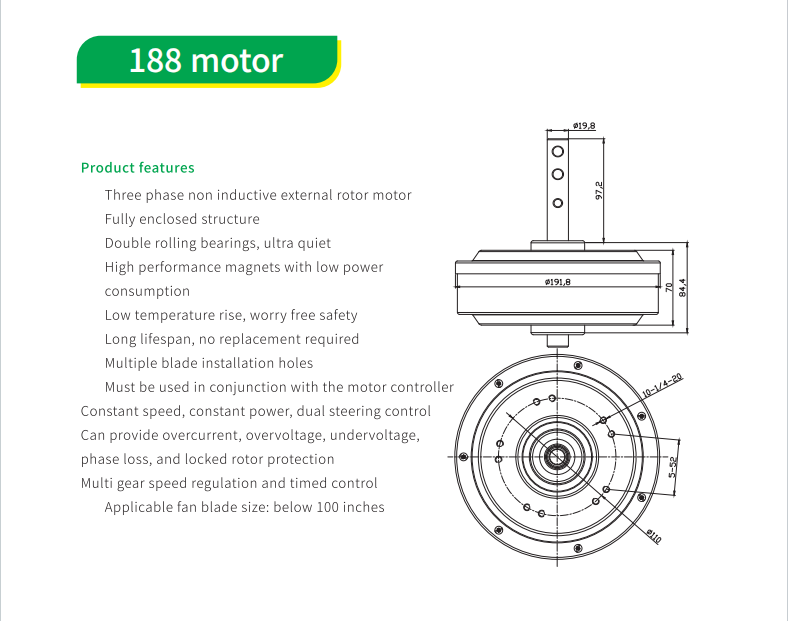

The 188mm brushless DC ceiling fan motor for 72–100 inch industrial HVLS fans is engineered for extreme airflow duty in factories, logistics hubs, and tall warehouses. As an industrial ceiling fan motor China solution, the platform combines a three‑phase external‑rotor architecture, double rolling bearings, and a fully enclosed housing to keep dust and moisture out of the drive section. The design objective of the industrial ceiling fan motor China platform focuses on stable torque at low rpm, long lifespan with minimal maintenance, and predictable performance under fluctuating grid voltage.

A dedicated 188mm BLDC ceiling fan motor factory develops the rotor system around high‑performance magnets and copper windings to deliver sustained output. The 188mm BLDC ceiling fan motor factory integrates precise dynamic balancing on every rotor to suppress vibration on 72–100 inch blades. Thanks to refined slot/pole matching, the 188mm BLDC ceiling fan motor factory delivers smooth commutation for continuous operation in production lines and assembly halls. Project teams using the 188mm BLDC ceiling fan motor factory platform benefit from standardized mounting holes that accelerate final assembly.

For applications requiring massive volume and low speed, the configuration behaves as a dependable high torque industrial fan motor. Oversized bearings and a thick steel stator core enable the high torque industrial fan motor to move large air columns while avoiding heat concentration in the windings. The control interface of the high torque industrial fan motor supports constant‑power mode, dual steering, multi‑gear speed profiles, and timer functions for shift‑based ventilation. Electronic protection in the high torque industrial fan motor covers overcurrent, overvoltage, undervoltage, locked‑rotor, and phase‑loss events.

Manufacturing execution is led by an experienced HVLS ceiling fan motor manufacture team with automated coil insertion, vacuum varnish, and 100% end‑of‑line load testing. The HVLS ceiling fan motor manufacture workflow maintains monthly capacity above project demand and holds buffer stock for urgent rollouts. Global OEM clients rely on the HVLS ceiling fan motor manufacture process to support consistent quality across multi‑site deployments, including new builds and retrofit programs for energy savings.

End users looking for turnkey ventilation value can specify a ready‑to‑integrate BLDC ceiling fan for factory package. The BLDC ceiling fan for factory configuration combines the 188mm drive, a matched driver board, and recommended blade kits for 72–100 inch diameters. With optimized torque curves and low acoustic signatures, the BLDC ceiling fan for factory bundle reduces HVAC runtime and improves worker comfort on machining floors. For procurement teams, the BLDC ceiling fan for factory solution simplifies sourcing, documentation, and compliance.

As a flagship industrial ceiling fan motor China offering, the system aligns with CE/RoHS requirements and supports UL‑ready documentation for North American projects. Long‑term field data from regional integrators confirm reduced energy consumption versus legacy induction motors. The modular harness design allows plug‑and‑play upgrades, and the industrial ceiling fan motor China ecosystem provides rapid after‑sales response with serialized traceability.

Engineering Highlights

External‑rotor, three‑phase BLDC topology tuned by the HVLS ceiling fan motor manufacture team for low‑speed, high‑torque operation on large blades.

Balanced rotor and sealed bearings from the 188mm BLDC ceiling fan motor factory to extend service life in dusty plants.

Controller toolkit for the high torque industrial fan motor: soft start, constant‑power, and programmable schedules for shift changes.

Proven deployments of the BLDC ceiling fan for factory bundle in metalworking halls, e‑commerce warehouses, and gymnasiums.

Production & Supply Capability

The production cluster behind the HVLS ceiling fan motor manufacture program delivers automated stator winding, thermal curing, and 48‑hour burn‑in on sample batches. Year‑round safety stock at the 188mm BLDC ceiling fan motor factory enables quick releases for seasonal demand spikes. With repeat orders from integrators across Asia, the Middle East, and Latin America, the industrial ceiling fan motor China network supports stable pricing and short lead times.

Integration & Customization

Engineering teams can request firmware tuning for networked BMS systems or wireless remotes. Shaft dimensions, flange patterns, and cable exits may be customized within the HVLS ceiling fan motor manufacture standards. For specialized airflow goals, the high torque industrial fan motor accepts different blade counts and profiles without compromising reliability.