These images show the production of magnet rings used in brushless DC motors. Workers and machines are assembling and processing aluminum castings, performing tasks such as finishing, deburring, and quality checks. The parts are neatly stacked, indicating high-volume production readiness.

This section captures the automatic stamping and lamination process for motor stator cores. High-tonnage stamping machines shape silicon steel sheets, which are then stacked to form the stator core. These machines ensure high precision and efficiency for mass production.

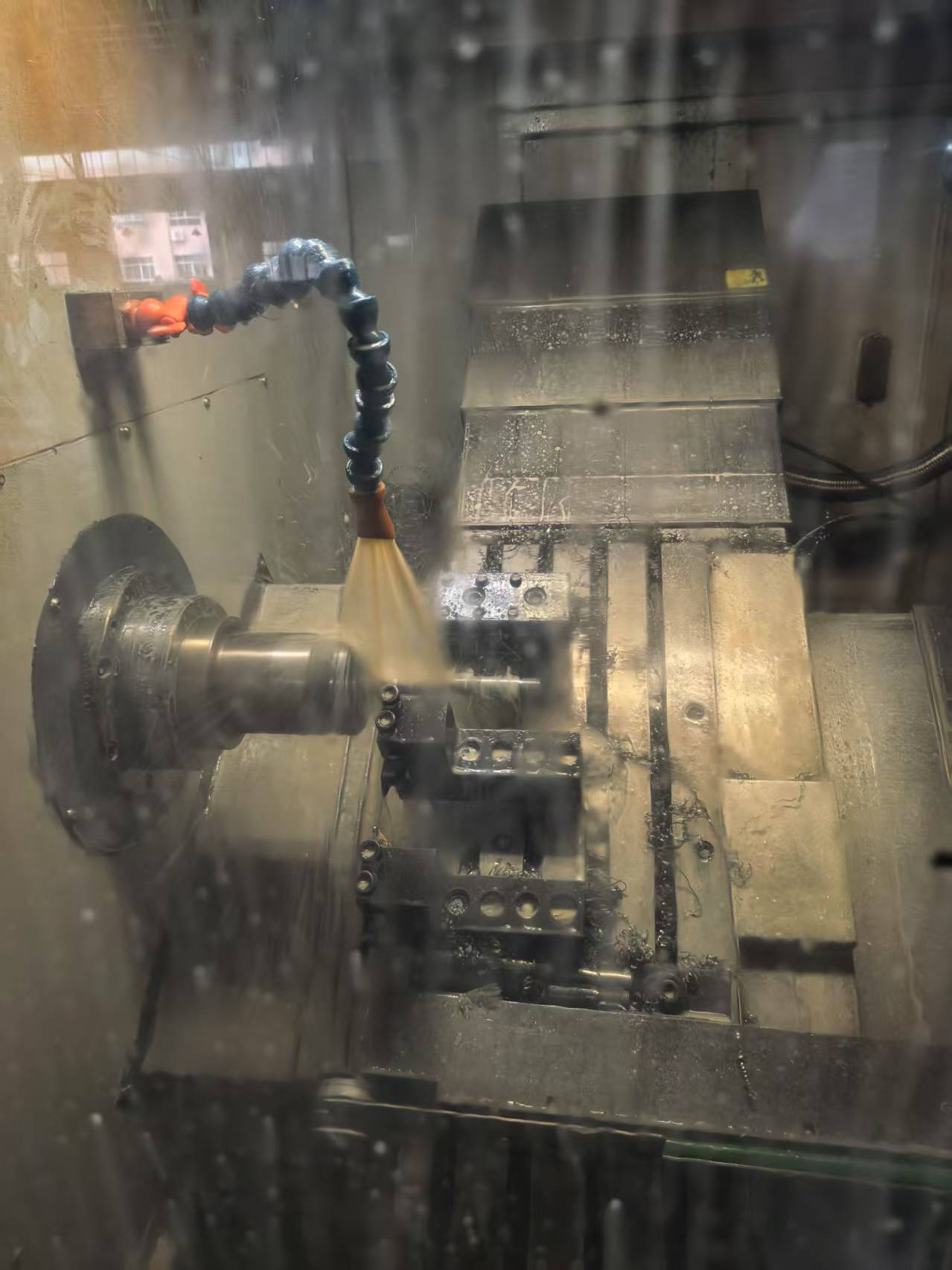

This image displays CNC machining of motor shafts, where the machine is performing high-precision cutting and drilling. The shafts are critical to motor rotation, requiring strict tolerances for smooth operation.

These images show the injection molding and assembly process for motor housings. Specialized equipment forms the outer casings, followed by possible integration with motor mounts or bearing seats. The housing provides structural protection and heat dissipation.

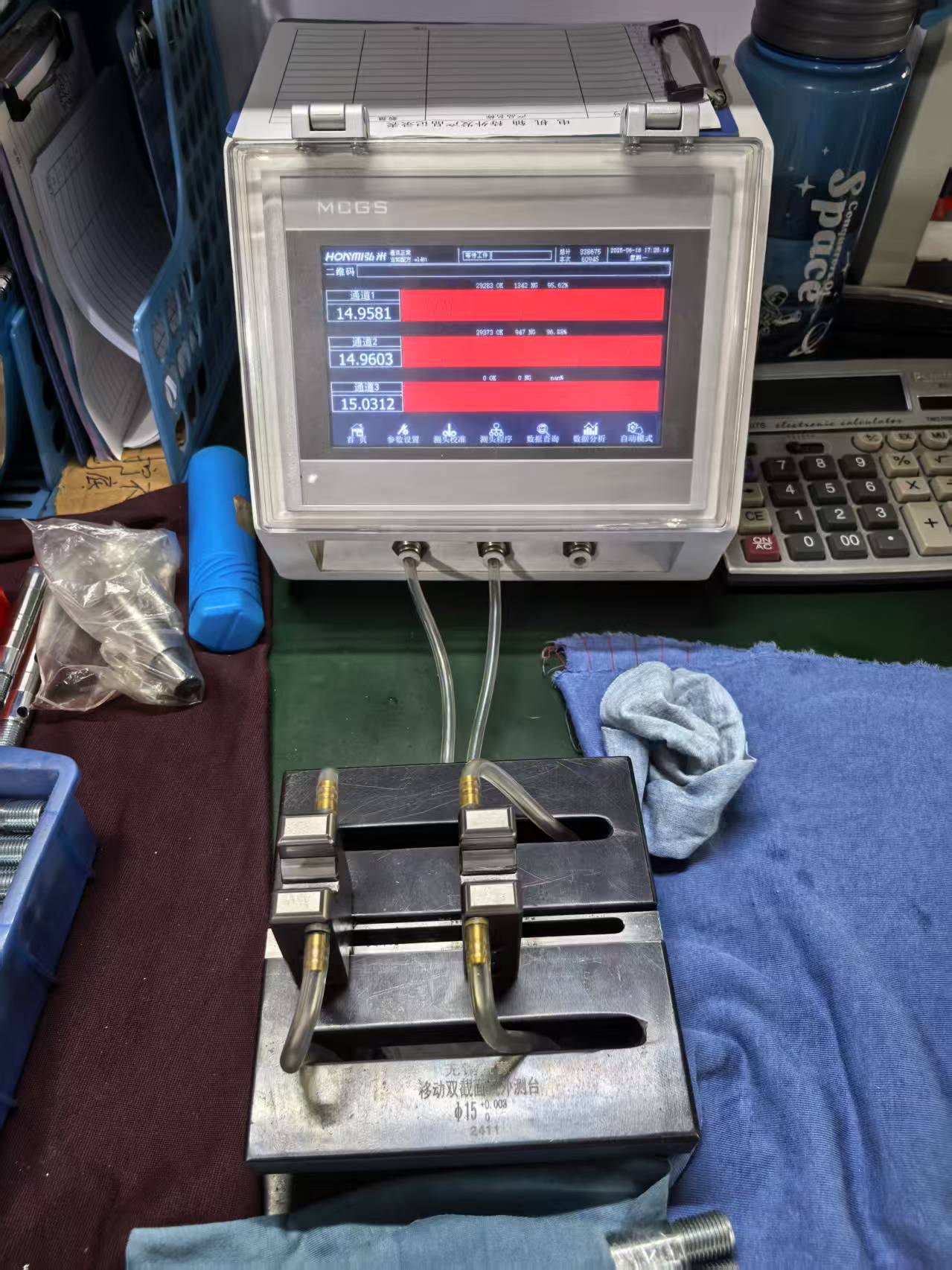

This image shows an air leak tester used to check the air tightness of motor end covers. The test ensures each cover meets strict sealing standards to prevent dust or moisture from entering the motor housing, which is critical for durability and performance in various applications.