Exhaust Fan AC Motor for Ventilation Systems | High Quality Single Phase Motor

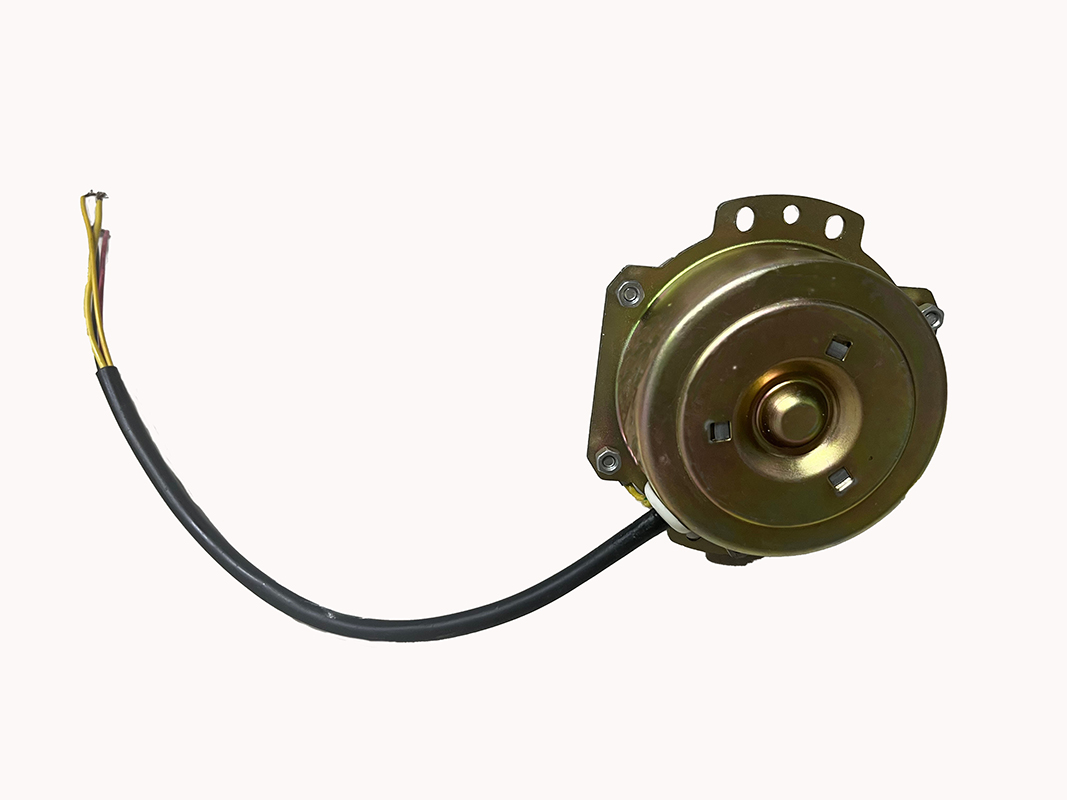

Product Overview

The exhaust fan AC motor provides dependable airflow solutions for commercial, industrial, and residential projects. Each ventilation fan motor is engineered with a robust single phase AC motor design that delivers steady performance, energy efficiency, and quiet operation. By choosing an electric motor for ventilation systems, customers gain reliable air exchange for kitchens, workshops, greenhouses, and public facilities. Every high quality exhaust fan motor undergoes rigorous testing to ensure compliance with international standards and to maintain exceptional durability under demanding conditions.

Applications and Use Cases

The exhaust fan AC motor serves a broad range of ventilation systems, from ducted exhaust fans in restaurants to wall-mounted ventilators in commercial buildings. A ventilation fan motor is critical in maintaining clean air and controlling humidity, making the single phase AC motor a preferred choice for easy installation and maintenance. An electric motor for ventilation systems supports OEM production lines, aftermarket replacements, and large-scale building projects. A high quality exhaust fan motor guarantees reliability for continuous operation in high-temperature or high-moisture environments.

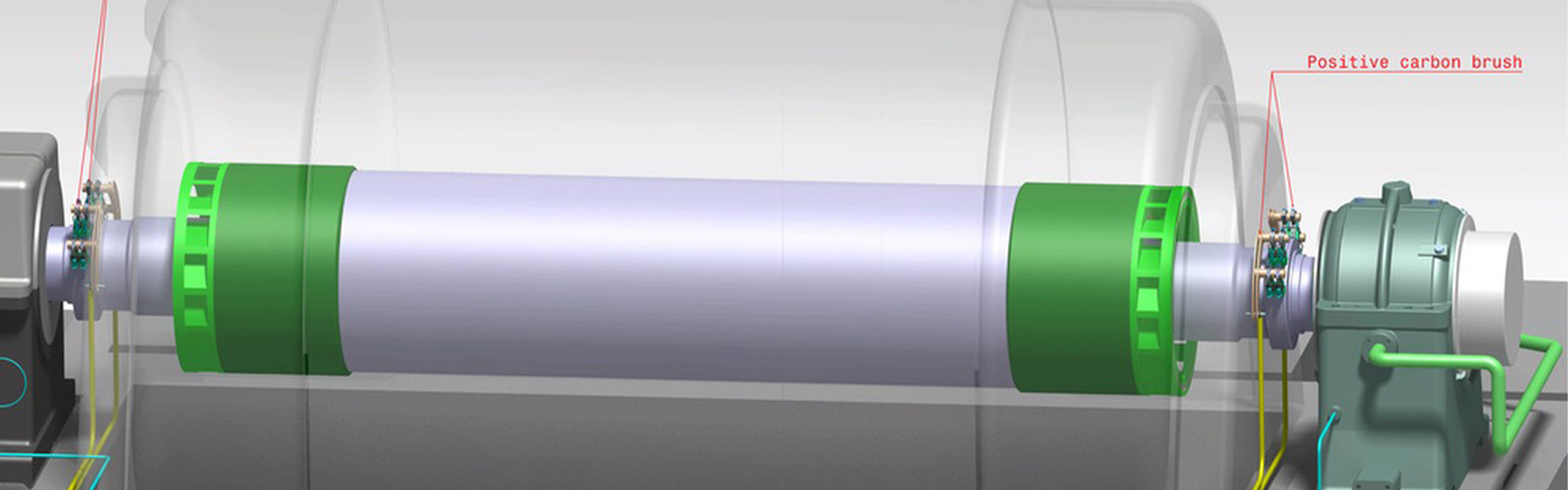

Technical Features and Advantages

The exhaust fan AC motor is crafted using premium-grade copper windings and laminated steel cores to achieve optimal magnetic efficiency. A ventilation fan motor benefits from precision-balanced rotors, reducing noise and vibration for smooth operation. Advanced manufacturing ensures each single phase AC motor offers consistent torque and speed control. An electric motor for ventilation systems includes thermal overload protection, sealed bearings for long life, and customizable voltage options. Every high quality exhaust fan motor reflects a commitment to innovation and reliability, backed by continuous research and development.

Production Capacity and Quality Control

The production facility manufactures thousands of exhaust fan AC motor units monthly, using automated winding machines and precision assembly lines. Each ventilation fan motor passes strict quality checks, from stator winding inspection to final dynamic balancing. The single phase AC motor production process includes 100% testing for electrical parameters and performance benchmarks. OEM and ODM orders for electric motor for ventilation systems are supported by an experienced engineering team and robust supply chain management. A high quality exhaust fan motor ships with protective packaging, clear labeling, and complete documentation to ensure customer satisfaction.

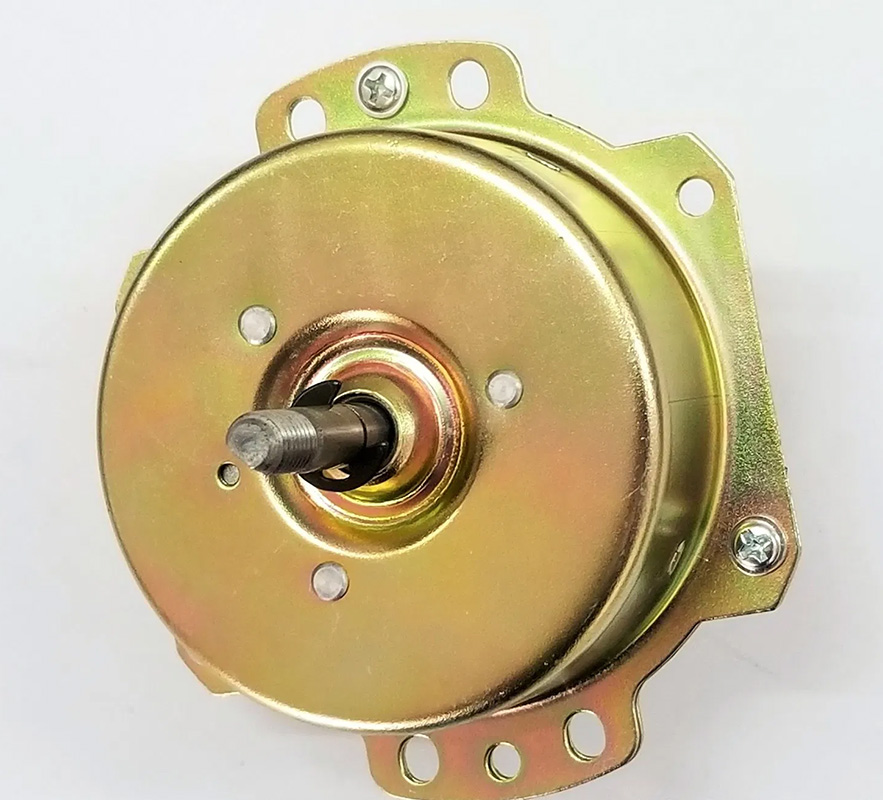

R&D and Customization Services

Investment in exhaust fan AC motor research and development enables customized solutions for regional standards and market demands. A ventilation fan motor can be tailored with different mounting brackets, shaft lengths, and connector types to match specific fan designs. The single phase AC motor supports variable frequency drive (VFD) compatibility for advanced control systems. An electric motor for ventilation systems supplier understands the need for flexible design to support HVAC contractors, equipment manufacturers, and wholesalers. Every high quality exhaust fan motor project benefits from expert engineering consultations and prototyping services.

Sales Network and Global Supply

The exhaust fan AC motor is supplied to HVAC and ventilation system manufacturers across Asia, Europe, and the Americas. A ventilation fan motor inventory is maintained for fast lead times and competitive pricing, with scalable production to meet bulk orders. A dedicated single phase AC motor sales team offers responsive service, technical support, and transparent communication throughout the purchasing process. Bulk procurement of electric motor for ventilation systems is supported with flexible payment terms and reliable logistics. A high quality exhaust fan motor is backed by international certifications to facilitate global trade and compliance.