The Fundamentals of AC Power and Magnetic Fields in Modern Motors

The operation of all ac electric motor units depends on the dynamic relationship between alternating current and electromagnetic fields. Unlike DC systems, AC power reverses direction 50-60 times per second, creating the oscillating magnetic fields essential for motor rotation. This principle forms the foundation for all voltage motor applications, from industrial pumps to household appliances.

Core Motor Types and Their Applications

Modern ac generator motor technology primarily utilizes two designs:

Induction motors - The most common general purpose motor type, using electromagnetic induction to create rotor currents

Synchronous motors - Precision customized motor solutions requiring separate excitation

Induction Motors: The Workhorse of Industry

The standard ac electric motor design features:

Robust construction ideal for voltage motor applications

Simple squirrel-cage rotors requiring minimal maintenance

Cost-effective general purpose motor solutions

These ac generator motor systems dominate applications needing reliable, maintenance-free operation, representing over 70% of industrial motor installations.

Synchronous Motors: Precision Performance

For specialized customized motor requirements:

Permanent magnet rotors synchronize perfectly with stator fields

Exceptional speed regulation (±0.01% variance)

Ideal for ac electric motor applications needing exact positioning

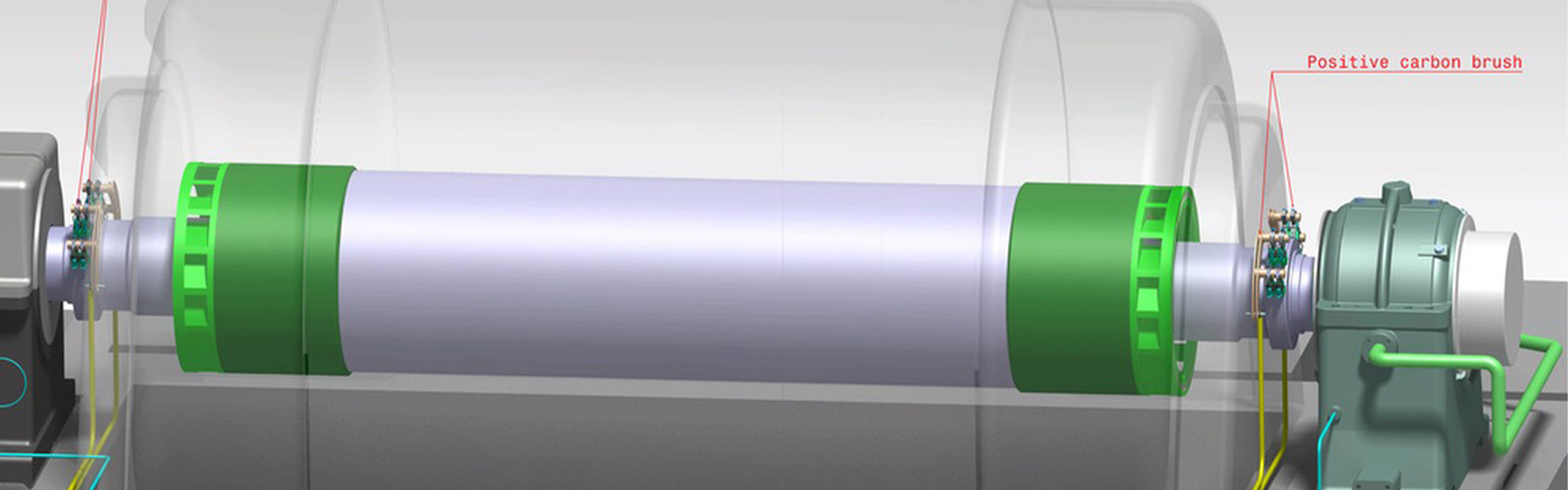

Critical Components: Stator and Rotor Design

Every voltage motor contains two essential elements:

Stator assemblies with precision-wound ac generator motor coils

Rotor configurations optimized for specific general purpose motor or customized motor applications

Modern ac electric motor designs feature:

Laminated steel cores reducing voltage motor eddy current losses

Class F or H insulation for ac generator motor windings

Advanced cooling systems in general purpose motor frames

Performance Optimization Techniques

Today's customized motor solutions employ:

Variable frequency drives for ac electric motor speed control

Smart sensors monitoring voltage motor performance

Advanced materials boosting ac generator motor efficiency

Efficiency Standards and Innovations

The latest general purpose motor regulations require:

IE3 premium efficiency levels

Optimized customized motor power factors (>0.95)

Reduced ac electric motor standby losses

Industry Applications and Future Trends

From HVAC systems using voltage motor designs to manufacturing plants relying on ac generator motor arrays, AC motor technology continues evolving. Emerging general purpose motor innovations include:

IoT-enabled customized motor monitoring

High-efficiency ac electric motor designs

Compact voltage motor configurations

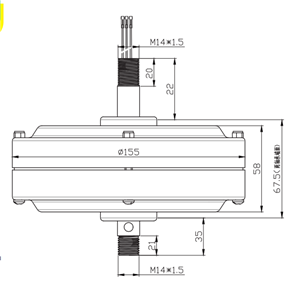

Technical Specifications Overview

Modern ac generator motor products offer:

Power range: 0.12kW-10MW

General purpose motor speed options: 900-3600 RPM

Customized motor voltage ratings: 110V-13.8kV

Ac electric motor protection classes: IP55-IP68

Installation and Maintenance Best Practices

For optimal voltage motor performance:

Properly align ac generator motor couplings

Maintain clean general purpose motor cooling vents

Regularly test customized motor insulation resistance

Conclusion: The Future of Motor Technology

The ac electric motor industry continues advancing with:

More efficient voltage motor designs

Smarter ac generator motor control systems

Versatile general purpose motor solutions

Highly specialized customized motor applications