Utility Model Patent Certificate

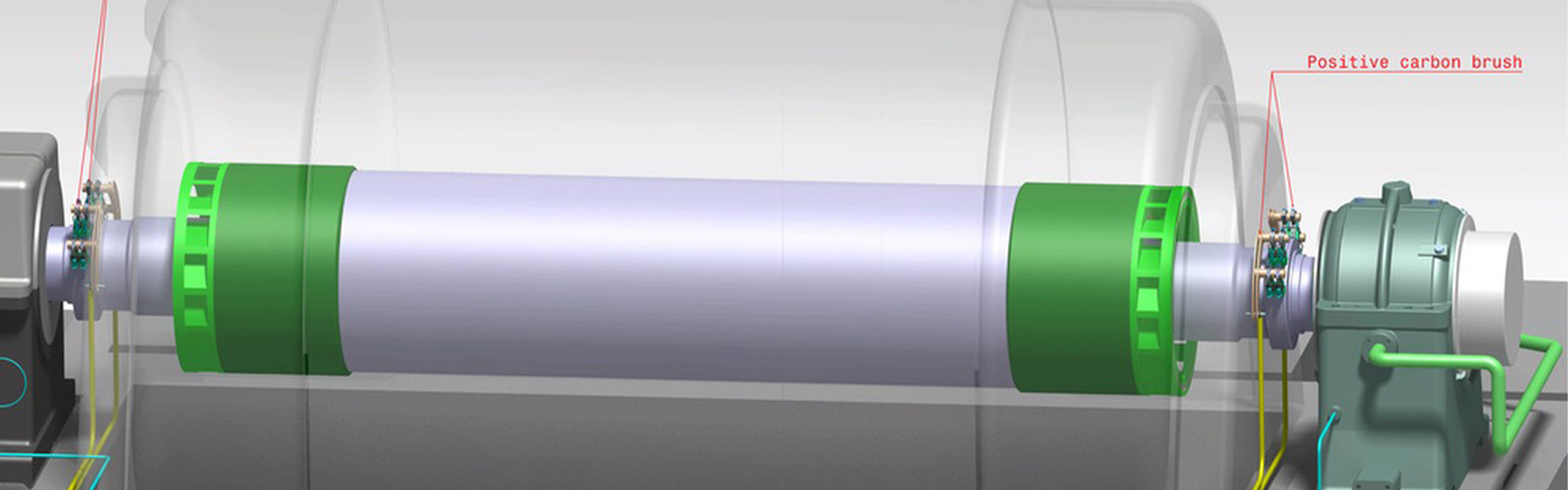

A DC brushless three-phase disc type external rotating motor

The utility model discloses a DC brushless three-phase disc type external rotating motor, comprising a housing and a bracket, wherein the inner wall of the housing is connected with a magnetic ring; A silicon steel sheet is arranged on the side away from the magnetic ring inside the shell, and a wedge-shaped groove is penetrated on the surface of the silicon steel sheet. A silicon steel sheet is arranged on one side of the outer wall of the bracket. This DC brushless three-phase disc type external rotating motor has eighteen wedge-shaped grooves on the surface of the silicon steel sheet, and hollow grooves evenly on the surface of the bracket. This structure can reduce the cogging torque by more than 50% during production and reduce the copper wire by more than 12% at the same power, greatly reducing energy consumption and improving production efficiency.

A small permanent magnet brushless motor for ceiling fans

This utility model discloses a small permanent magnet brushless motor for ceiling fans, comprising an upper shell, a lower shell, a shaft, a magnet, and an iron core. The upper shell and the lower shell are fixed, the shaft is set at the center of the iron core, and the magnet is set on the outside of the iron core. The outer wall bottom of the upper shell is integrally formed with an upper support ear bent outward; The top of the outer wall of the lower shell is integrally formed with a lower support ear that bends outward; Both the upper and lower ears are equipped with mounting holes; Also equipped with screws and nuts; The upper and lower ears are attached and fixed with screws and nuts. The structure of this utility model is reasonably designed, with upper support ears on the upper shell and lower support ears on the lower shell. During assembly, the upper and lower support ears are attached and fixed with screws and nuts, which helps to reduce the thickness of the magnet and thus reduce the overall structure thickness. At the same time, it can also reduce the overall diameter size, making the motor more compact and meeting the needs of small ceiling fans. It has strong applicability and good practicality.